In an era when finding restaurant employees is harder than ever, technologies that reduce the number of variables in producing consistent food are a major boon to quick-service operators. Though it can be a somewhat daunting task to remake every kitchen belonging to a given brand, the move is a necessary step in bringing technology into the twenty-first century, and in the long run, it can save brands money—and headaches.

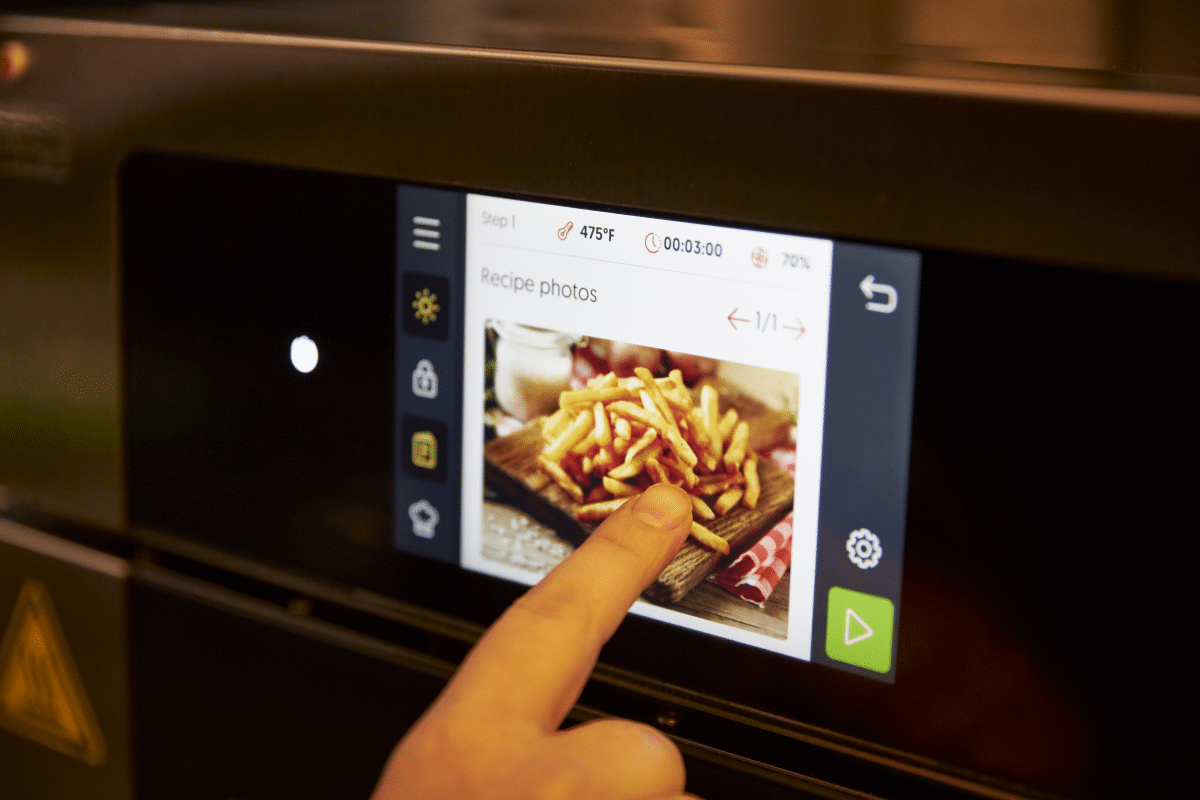

The biggest advantage of implementing smart ovens, and a central management system that creates a single dashboard control for all of those ovens, is the ability to cook food the exact same way across locations. By pressing a button, every kitchen instantly has a new recipe setting on their smart oven. The selection can be brought up by kitchen employees for the specific item, and with a press of a button on their hand, that menu item is cooked to order exactly how the brand strives to make it.

Tim Murphy, product specialist with Alto-Shaam, has been helping a swath of brands upgrade their cooking game over the past six months, introducing Alto-Shaam’s new cloud-based remote oven management system. ChefLinc is compatible with the Vector H Series Multi-Cook ovens. He says that just as important as seamlessly adding recipes to ovens is the ability to take the old ones out.

“Removing old recipes that create digital clutter decreases the chances that employees will use the old recipe instead of the new one,” Murphy says. “Whether it’s just more comfortable for them or they accidentally revert to the old recipe by being forgetful, that’s an issue many brands deal with—ChefLinc assures uniform cooking of new recipes.”

Brands that haven’t made the switch know all too well how costly and laborious rolling out new menu items and LTOs can be. The logistics of getting recipes printed, laminated, and sent to remote store locations is cumbersome to say the least. With smart oven technology, small tweaks turn into big changes.

“Let’s say you go out into the field and decide your pizza isn’t dark enough,” Murphy says. “You could literally change everyone’s pizza setting in one stroke and now everybody has the update. And now you don’t have to train anybody on a new recipe because the update has been done, and staff might not even know that.”

Another advantage of smart ovens and a unifying software platform is the ability to check oven usage remotely. That can lead to a greater understanding of asset management, for example, knowing which ovens are being used up to capacity, or which stores could benefit from an additional oven.

“So let’s say I’m managing a region and somebody calls me from the field and says, ‘I don’t have enough capacity, my oven can’t keep up,’” Murphy says. “I can literally go online, look at their oven and know whether or not they’re telling the truth. There’s no homework. You know exactly how much downtime that oven has.”

A final reason to make the switch is the reduction in repair costs. If something goes wrong with the product, the guesswork is taken out of the equation with detailed service data on screen. Too often operators are blindsided by an equipment error, with no visibility to the issue until arriving at the location. Further complicating the situation, service error codes are often vague and uninformative. This lack of detail extends oven down time as operators wait for service providers to travel to the location and run required tests to determine cause of the error before proposing a solution.

“We are so excited about this product, and all of the operators we talk to who have it installed are just as excited,” Murphy says.

To learn more, please visit alto-shaam.com/cheflinc.

By Charlie Pogacar