White Castle has been around 102 years, give or take a month or two. A journey that began when Billy Ingram and Walter Anderson began dishing square hamburgers for 5 cents apiece. Still family owned, the brand’s guidepost remains nostalgic—“Create Memorable Moments.” Yet how White Castle plans to deliver this promise is anything but old-school.

Roughly three years ago, the venerable brand began exploring two initiatives better suited for The Jetsons than a tale on fast-food’s original player. One was what’s become a highly publicized partnership with Miso Robotics and its “Flippy (now Flippy 2)” robot, which essentially takes over the fryer station. The other was a deal with Mastercard on drive-thru AI. Dubbed “Julia,” the technology takes and processes orders with customers every time they cross the loop detector.

This timeline is vital to understand, Michael Guinan, White Castle’s VP of operations services, shared at RestaurantSpaces. “If you are not already in robotics and you do agree that it’s coming, I suggest you do it sooner than later,” he says.

In the three years since collaboration, Flippy has entered 10 White Castle locations, with plans to reach 100. The AI “Julia” is just about to go into its third, but should be able to scale quickly on a regional level once everything settles. The broader point, however, is the so-often labeled “restaurant of the future” is a vision materializing quickly as COVID’s dust clears, Guinan says. But implementation isn’t overnight.

You have to start by asking “why,” he adds. For White Castle, the reasoning supports a turned-over mindset that’s flooding quick service in general—this notion AI and robotics aren’t there to replace hospitality; rather, they’re tools designed to amplify guest satisfaction for a new age of running restaurants. Or, in White Castle’s case, using innovations like Julia and Flippy to “Create Memorable Moments.”

Susan Carroll-Boser, White Castle’s CIO, is firmly in the camp of those who believe AI will “change everything.” As soon as a few months ago, she wasn’t. But when she asked a 150-plus person crowd of operators, vendors, and suppliers if they’ve used ChatGPT, more than half raised their hand. “All of you are beginning to realize it’s coming,” she says. “It has been for 15 to 20 years … but this is not just your grandpa’s robots that you used to see in the 70s that were manufacturing our cars. These are robots that are able to make decisions, learn from things, protect humans, and stay out of their way.”

Conversational AI is on deck. Beyond just being able to take an order, the technology is learning to adapt to the guest and have an intelligent back-and-forth. “That’s taking, at least in [quick service], taking it by storm,” she says. “Think of that idea of being able to take an order, and it doesn’t need to just be at the drive-thru.”

Guinan says White Castle was drawn to this technology for reasons touted by industry peers. “Let’s call it what it is,” he says. “We are struggling to get enough labor on the floor. Julia is not taking a job away from anyone.”

“Imagine the ‘connected restaurant,’” White Castle’s Susan Carroll-Boser says, “where every door, all equipment, every loop detector is connected.”

Recently, at one of the locations with drive-thru voice AI, a crew manager told Guinan, “Julia just went on the night shift.” Then added, “Oh my God, she just kept taking orders.”

While light-hearted, it was an observation Guinan circled. Historically, employees often place customers on hold so they can task something else. It’s not necessarily a sign of bad customer service—it’s just the reality of operating a high-volume quick-serve. White Castle’s “drive-thru customer service specialists” take the order, but have four or five other jobs happening simultaneously: Take the order, put down the order, make the drink, get the order ready, hand it out. “And now, our mission for the company is to Create Memorable Moments. So we just relieved that person from taking the order, which allows them to greet the customer at the window or the hospitality door and say, ‘you had yada, yada, yada, your total is this, how are you today,” Guinan says. “And so, it allows that little interaction to create that memorable moment, which is what we’re striving to do. Technology creates that value proposition.”

Julia, in turn, lifted customer experience and, because it can be programmed, always works to drive basket size. Additionally, it created a better job inside the restaurant for the people already working there.

The natural language processing behind the technology has come a long way. It’s working to evolve past the Alexa and Siri systems where you don’t just need to talk to the device, but you have to talk to it in a specific way. Conversational AI is trying to have a conversation and learn the cadences and nuances in people’s speech to make it feel less robotic.

The backbone and progression of Julia rings familiar with Flippy, too. When Miso Robotics first presented the technology to White Castle, it was intended to do exactly as its name suggests—flip food. Miso Robotics called White Castle and said they’d like to bring the tech to the drive-thru.

White Castle and Miso Robotics began working together in September 2020 with the original “Flippy” at a Chicagoland restaurant. Following a November 2021 upgrade to Flippy 2, White Castle started to see impacts with potential to scale. In fact, many of the model improvements stemmed directly from White Castle feedback.

While Flippy’s first iteration helped employees stay in designated locations, workers noted a need for human assistance on both sides of the robot—from the initial point of contact with the uncooked product to when the cooked food gets placed in the holding area—requiring one or two employees at several steps. Basket management wasn’t automated, so the cooking process didn’t end up all that seamless.

That’s where the Flippy 2 refresh came in. The robot, which takes over the fry station in an effort to free up workers for other tasks, added an “AutoBin” system for lower volume and specialty foods such as onion rings or chicken tenders. Each bin could now hold as much as a full fry basket, and be customized for a kitchen’s specific needs, or delineated for individual products such as vegetables and fish to prevent cross-contamination.

Flippy 2 performs more than twice as many food preparation tasks compared to the previous version, including basket filling, emptying, and returning.

Once the product is placed in the bin, AI vision identifies the food, picks it up, cooks in the correct fry basket, and places in into a hot-holding area. Eliminating the transfer lessened human-to-food contact and decreased potential oil dripping and burns caused by lifting and moving baskets. And to findings from White Castle’s pilot, there was now a closed-loop system where Flippy 2 operated on its own without human intervention in the middle of the process. The end result was throughput 30 percent higher (roughly 60 baskets per hour). Flippy 2 also took up less space in the kitchen, including 56 percent reduced aisle intrusion and 13 percent height reduction.

And so, White Castle began to envision 100 stores with Flippy 2.

White Castle has 11 freezer-to-fryer items, Guinan says. The brand invested in computer vision so there are no buzzers or timers. Everything is done through computer vision and learning. Flippy, via the product identification mentioned earlier, knows exactly what it’s picking up and what it’s cooking. The hopper holds two menu items (usually fries and then onion chips or chicken rings) and is able, when an employee pushes a button, to slide over and grab the basket size it’s asking for. Then, it cooks.

Simply put, an employee doesn’t have to do anything other than call and collect. The other nine freezer-to-fryer items go into the auto bins (there’s a camera for each of those). Flippy swings, grabs, cooks, and delivers to employees. “All we have to do is package it,” Guinan says.

In a lot of its stores, White Castle has gone from having two employees, because its fryer line is split—sandwich goes one way, sides go another—to where all food now heads in the same direction. White Castle is then able to take that second employee and repurpose them. Say, get them in the window to help make that favorable impression Guinan talked about. “Helps with orders and speed of service,” he says. “Why does operations want this? Again, it’s able to repurpose a body. Or, when we are very short, one of the GMs said to me, ‘I can always count on Flippy to be there.”

The food has been more consistent and cooked to temperature as well.

A view into the future of fast food

Carroll-Boser points to the manufacturing industry as a harbinger of what’s to come for restaurants. “We know anytime you have a bottleneck it is hurting your entire factory. Well, it’s hurting our entire restaurant,” she says.

White Castle’s fryer had become its bottleneck. “You had to be almost an octopus to run the fryer,” Carroll-Boser adds.

She also loves the idea of solving what’s been a fast-food quarrel for as long as the category has existed (when A&W or White Castle started it, depending on whom you ask). “Our team members do not like doing portion control,” she says with a laugh. “You know they don’t like using their scoops of the world.”

White Castle has eight cameras in the back of the house watching what’s happening at any given time. “It will let you know when something is out of order,” Carroll-Boser says.

Guinan adds Flippy has six different sensors that, if broken, stop the robot.

So where is Flippy going next, aside from more locations? Guinan says White Castle is working to develop POS integration where Flippy can drop certain items based on the flow of business and sales trends. Basically, the brand would be able to use transaction data to cook ahead and predict order flow. “We do product projections now,” Carroll-Boser says. “But whether or not people really cook to that projection, especially if they’re really busy, is a hard thing.”

During peak periods, White Castle employees can manage as many as six baskets and have to be well-versed to helm that fryer area. They have to be griddle masters to operate the griddle. “So back to our mission of Creating Memorable Moments,” Guinan says. “There’s nothing memorable about that for the team member and the customer. Getting that team member more customer facing is going to help us.”

One tech arena Carroll-Boser considers a whiffed opportunity for restaurants is the connection of AI and IoT (the Internet of Things). The concept has a convoluted moniker for a straightforward definition: If you have a freezer connected to the internet, you have IoT in your restaurant. But that’s Generation 1 IoT, Carroll-Boser says. White Castle, for instance, has a lot of IoT built around food safety in its restaurants.

“What are we missing?” she asks. This, too, pulls lessons from manufacturing, where every machine is connected to the internet these days. Those operations do so, Carroll-Boser says, to prevent down time and the loss of revenue. “They can’t be down. We can’t be down, either,” she says of restaurants.

It about more than predictability. “It’s also about getting the information about what’s being used and not used,” Carroll-Boser continues. “For us, the lesson is going to be, we tell our employees how to run Castles. When we go to understand why we’re slow or when we have a problem or why we had a problem or when we’ve had bottlenecks, it’s been hard for us to know because we’re not connected.”

That, in a summary, is Carroll-Boser’s view of the “restaurant of the future.”

“Imagine the ‘connected restaurant,’” she says, “where every door, all equipment, every loop detector is connected.”

It’s a universe that’s going to take a lot of cabling to make happen from a logistical angle, Carroll-Boser adds.

Where does AI come in? In the case of the “connected restaurant,” operators are going to be flooded in data. It’s why everyone tends to be specialized in their own fields in IoT. “It’s kind of like when we started off in the beginning of restaurants,” Carroll-Boser says. “Where we collected our basic metrics and we’ve grown and we’ve grown. Buildings are growing. Everything in the building now is data and we have to have that data.”

Guinan provides an operational example. While in Orlando with COO Jeff Carper and CEO Lisa Ingram (where the world’s largest free-standing White Castle is), the group was chatting through whether or not it should open another line. How could it educate entry level crew managers running shifts, or GMs, on how or when to do so? “So, having this technology, to be able to say, you need to set another griddle based on the volume, based on the demand, you need to set another griddle, you need to come off that line and bring all your team members to one line,” he says. “That’s true technology that can take our management, our team members, to the next level.”

“People who don’t set the griddles when the griddles are there waiting to be set, those are more customers not being served,” Carroll-Boser adds. “So the idea of having it connected, AI solutions for all of our equipment, is very important.”

Plainly, it will help White Castle move past the “gut feel” era of running restaurants. The equipment watches a pattern, observes history, and then triggers real-time fixes. “That would be huge for us,” Guinan says.

When White Castle has a bottleneck, often it’s tied to speed of service. It doesn’t know if the capacity problem is due to people who haven’t set griddles or employees who have run out of space on them. “We know how many people are there, but we don’t know what they’re doing,” Carroll-Boser says.

Returning to the example of Julia’s AI drive-thru experience, Guinan says there was a broader lesson for White Castle. Customers were driving up, but they were put on hold, as shared earlier. Julia keeps taking orders every time a guest crosses the loop detector. “We solved the problem for them and for the company,” Guinan says. “And I suspect their sales are probably going to be higher and their customer experience is going to be better because Julia just keeps taking orders and we keep fulfilling orders. Imagine if we can have that on our griddles and our fryers and all our equipment to make that manager and GM’s job a little bit easier.”

Carroll-Boser elaborates on the connection with computer vision. In the past, the technology was mostly a neutral concept. They’re there, but employees look at the footage later. A human still must review and process. Computer vision in quick service surrounds one major, potential topic, she says.

Picture cameras in parking lots but looking at cars to let operators know how long a car has been there. Specifically, how many cars are behind the menuboard in the stack. The computer can learn and let restaurants know when things have gone too high. It would unlock a world of new metrics, Carroll-Boser says.

White Castle tracks speed of service at the drive-thru by when someone crosses the loop detector, gets their order taken, and then has their order bumped and handed out. “As a customer, you view your experience the minute you pull up in that line,” Guinan says. “So if you’re five cars back, that’s when your experience started. For us to have that knowledge to truly understand how long customers are waiting, I know it’ll help us make our decisions differently.”

Carroll-Boser expects restaurant design to follow these threads. Stores will be built for aesthetic reasons, as always, yet also with AI functionality in mind. Can they be created to hide cameras in plain sight? Can automation enter the back of the house to improve the oft-narrow, long-winded flow of a quick-service box?

Just take Flippy. One reason White Castle was deliberate in the rollout is a detail as granular as hoods. It’s had to change position (it takes 48 hours for Miso Robotics to walk in and get it live, a bit longer for White Castle’s construction crews to accommodate), low, high, left, or right. Another challenge is trying to chip away at the downtime required for each install. But for its “Castle of the Future,” Guinan says, the game-changer won’t necessarily be a flashy development; it will be flexibility.

Because the reality is, whatever changes White Castle makes today to embrace technology, might be outdated in three years when the next grand element arrives.

“We need flexibility within our restaurants that help us adapt to the future,” he says.

“Please build me a web of walls that has cabling capabilities everywhere,” Carroll-Boser adds. “Thinking about tunnels, web tunnels. That will allow the flexibility of your spaces to change. Not just the size, but also the walls and the infrastructure. Thinking of building a highway that’s coming outside with lots of infrastructure for the future.”

More widely, these innovations simply can’t be put on hold. Carroll-Boser says restaurants need to ahead of pressing issues instead of trying to outlast them. “We can’t wait and wait and hope that the next generation produces a line of children who are willing to come and work with us and grow up with us and our company,” she says. “Voice AI is coming.”

Sidebar: A quick cost view of automation

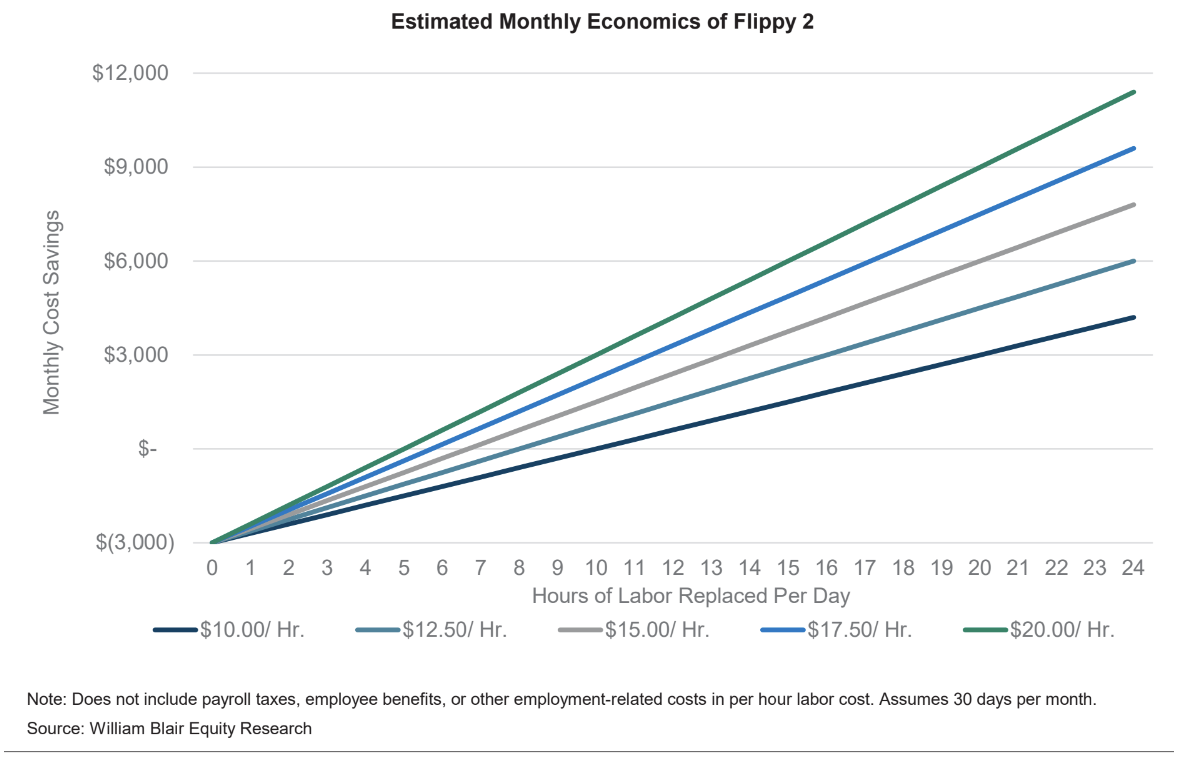

William Blair analyst, Sharon Zackfia recently published a whitepaper on automation. She outlined some details around Flippy and its potential ROI. She said Miso Robotics’ Flippy 2 and Flippy Lite are offered via a robot-as-a-service (RaaS) subscription model, in which one-time installation fees are followed by monthly subscription fees starting at $3,000 for Flippy 2. “Subscriptions include the equipment alongside routine maintenance, service calls, and live support,” she wrote. “Based on Miso’s calculations, the $3,000 subscription fee is offset by labor savings for restaurants that serve lunch and dinner, with meaningful leverage for restaurants that operate longer hours. Because the subscription cost is fixed [versus the inherently variable cost of labor], high-volume restaurants with high average hourly pay would be best positioned to recognize cost savings with Flippy, as we estimate breakeven at a relatively high six to seven hours of labor per day [assuming pay of $15 per hour].”

Flippy 2 is far from a White Castle phenomenon. It’s working with Jack in the Box, Wings and Rings, and Buffalo Wild Wings. “Chipotle is also testing a customized version of Flippy Lite, Chippy, to cook and season tortilla chips in a California restaurant, which if successful would bolster in-stocks of tortilla chips and reduce waste, while also im-proving the employee experience as frying tortillas in very hot oil is one of the least desired tasks at Chipotle. Still, installation of Chippy would likely necessitate remodels and permits, as it needs to be under a ventilation hood, and initial prototypes were too large to seamlessly fit in Chipotle’s restaurant workflows,” Zackfia wrote.